The CO2 gas from the stripper is cooled and led to a series of purifiers system to remove the impurities and compressed in a non-lubricated two-state compressor to a. Reagents 7 1 Deiomzed distilled water Prepare by passing distilled water through a mixed bed of cation and amon exchange resins Use deiomzed distilled water for the preparation of all reagents calibration standards and as dilution water 7 2 Nitric acid cone If metal impurities are found to be present distill reagent grade nitric acid m a borosilicate glass distillation apparatus or use a.

Energy Saving Co2 Absorption Process Escap Nippon Steel Engineering

Aidic It

Flowchart For Co 2 Recovery From Flue Gases Using Mea Dea And Mdea Download Scientific Diagram

Consider Water H 2 O for an example.

Mea absorber water recovery. Remove recovery bottle cap and add coolant using a funnel. The lean MEA is again fed to the absorber tower through the MEA cooler and a pump making it closed-loop. Hydrogen fuel will be sold for roughly 10kg ODell 2015.

It is a common unit process used in refineries and is also used in petrochemical plants natural gas processing. Congratulations to my chairman Dr Vaughn Starnes 100th AATS. What an amazing virtual aats.

The Recovery of Hydrogen. Methane will be purchased for 0226 per kilogram US. 32 Full PDFs related to this paper.

A kettle reboiler Figure 101 consists of a horizontally mounted TEMA K-shell and a tube bundle comprised of either U-tubes or straight tubes regular or finned with a pull-through type T floating headThe tube bundle is unbaffled so support plates are provided for tube support. There is also one mole of oxygen atoms weighing 1600 grams in the mole of water. For example if MEA can be used at 40 wt and other issues controlled via additives the reboiler energy demand can be reduced to.

Aeration of raw water to convert iron from dissolved ferrous state to insoluble ferric. Amine gas treating also known as amine scrubbing gas sweetening and acid gas removal refers to a group of processes that use aqueous solutions of various alkylamines commonly referred to simply as amines to remove hydrogen sulfide H 2 S and carbon dioxide CO 2 from gases. Process of treatment is aeration flocculation clarification and filtration.

1206-1218 2011 Luyben showed that operating the absorber at an elevated pressure reduced Acetone losses but increases vent losses and raises the required temperature and cost of the vaporizer heat source. One mole of water is 180152 grams. 109 Likes 2 Comments - Dr Raymond C Lee MD drrayleemd on Instagram.

Full PDF Package Download Full PDF Package. In that compound there are two moles of H atoms and 2 x 1008 2016 grams. Liquid is fed by gravity from the column sump and enters at the bottom of the shell through one or more nozzles.

Increasing concentrations of greenhouse gases GHGs such as CO 2 in the atmosphere is a global warming. The addition of a wash water section to the absorber can reduce the MEA evaporation significantly down to 028 kgton of CO 2 004 ppm at the expense of increased capital costs. The effectiveness of such scheme will be measured against naphthenic acids derivative percent recovery in the wash water.

Everything in the simulation converged except the recycle stream that is coming from the stripper to the absorber. The results indicate the electrostatic conditions can facilitate the recovery of the naphthenate salts post neutralization with high recovery rate of average of 706 with 30 water wash volume in a single-stage contact observed over 12 hours steady-state operation. The rich solvent is then sent to the stripping column where CO 2 is released at temperatures over 110C and vacuum pressure.

The plant has been designed to produce 560 m3hr. Sulfur recovery converts hydrogen sulfide in sour gases and hydrocarbon streams to elemental sulfur. Multistage gas compressors move gas into a vapor-liquid separator called a KO or knockout drum which removes water and liquid hydrocarbons from the gas stream.

MEA will be purchased for 050 per kilogram Alibaba 2015a. However expensive is a subjective as opposed to objective term. Coupling of Absorber and Stripper Absorbers are frequently coupled with strippers to permit regenerationdlifthbbtor recovery and recycling of the absorbent Stripping vapor Stripping vapor Because stripping is not perfect recycled absorbent contains solutes absorbates.

The process has two distillation columns and an absorber column in which a water stream is used to recover acetone. 2 Full PDFs related to this paper. Thats how many grams of hydrogen are present in one mole of water.

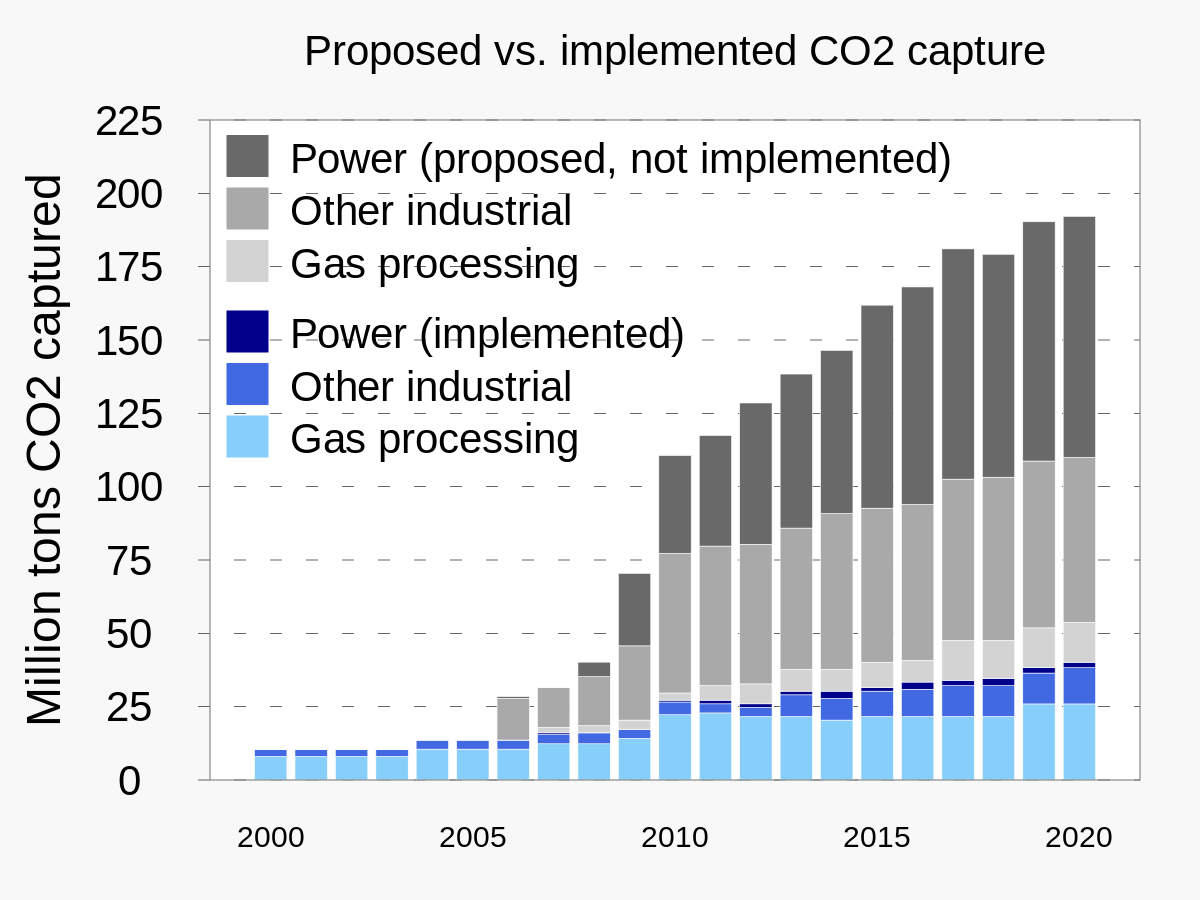

CHAPTER FIVE Direct Air Capture INTRODUCTION. Human activities are a major cause of increased CO 2 concentration in atmosphere as in recent decade two-third of greenhouse effect was caused by human activities. An initial reaction some people have to CO 2 capture technology is that it is expensive.

A typical process produces elemental sulfur by burning hydrogen sulfide under controlled conditions. It should be noted that addition of anti-foam is needed in the absorber and solvent degrades due to the presence of oxygen and stripper temperatures. 748 x 10 8.

Cooling System Pressure Test MAINTENANCE Cooling System Pressure Test Carefully straighten any bent radiator fins. 2 MEA solution is heated to release almost pure CO 2The lean MEA solution is then recycled to the absorber. Do Fill recovery bottle to MAX level with Polaris 6040 not dilute with water.

Polaris Premium 6040 is already premixed and ready to use. A short summary of this paper. Advanced MEA processes are also being developed where MEA is used at concentrations greater than 30 wt and additives are used to control degradation and corrosion.

The absorber is operated at 40C and a pressure around 6070 bar. The most widely used recovery system is the Claus process which uses both thermal and catalytic-conversion reactions. Standard Methods For the Examination of Water and Wastewater 23nd edition 2017.

The results of recent integrated assessment modeling Fuss et al 2013 have made clear the need to include negative emissions technologies NETs as one component in a portfolio of solutions eg mitigation energy efficiency renewables fuel-switching to prevent greater than 2C global warming by 2100. Water treatment plant The sour water is Tube wells. 211 where CRCp capital recovery cost of replacement parts yr Cp initial cost of replacement parts including sales taxes and freight Cpl cost of parts-replacement labor CRF capital recovery.

Carbon capture and storage CCS is a major strategy that can be used to reduce GHGs emission. Dental water line operating conditions are especially appropriate for Legionella proliferation because the water is stagnant a majority of the time the narrow plastic tubing encourages biofilm formation and the water temperature is usually 20 degrees C 68 degrees F or higher-some systems maintain water at 37 degrees C 986 degrees F. The untreated sour gas enters an amine absorber where API 610 circulation pumps inject aqueous amine solutions containing molecules that bind onto CO2 and H2S.

Using the standard chemical engineering design which may not necessarily required for the air capture process the total estimated cost for this process was around 1690ton CO 2. 2021 ASHRAE Handbook Fundamentals I P. The water will be sold at 000207 per kilogram Freeport Water 2014.

The annual cost of the replacement materials is a function of the initial parts cost the parts replacement labor cost the life of the parts and the interest rate as follows. I am simulating a CO2 capture unit with MEA amine. And there are 7 tube wells with a draw capacity 100m3hr.

1

Diva Portal Org

.jpg)

Amine Strength In Absorption And Regeneration Solutions

The Pfd Of The Conventional Co 2 Capture Process Using Aqueous Mea Download Scientific Diagram

Trimeric Com

Netl Doe Gov

Carbon Capture And Storage Wikipedia

Energy Minimization Of Mea Based Co2 Capture Process Sciencedirect